QForm Group is a leading developer of software for simulation and design of metal forming processes

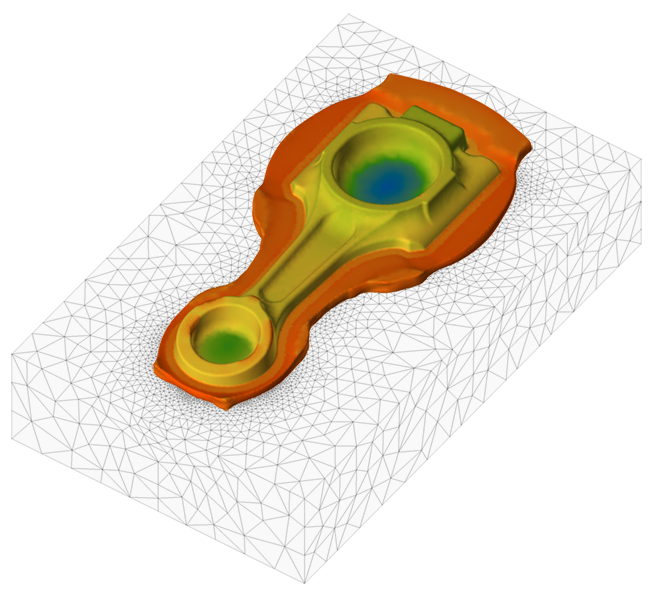

QForm UK General Metal Forming

QForm UK is a professional engineering software used for simulation, analysis and optimization of metal forming processes providing excellent reliability. It covers the essential needs in metal forming simulation for large and small forging companies as well as research and educational establishments. QForm UK provides simulation of an entire technological chain and a wide range of possibilities for process analysis.

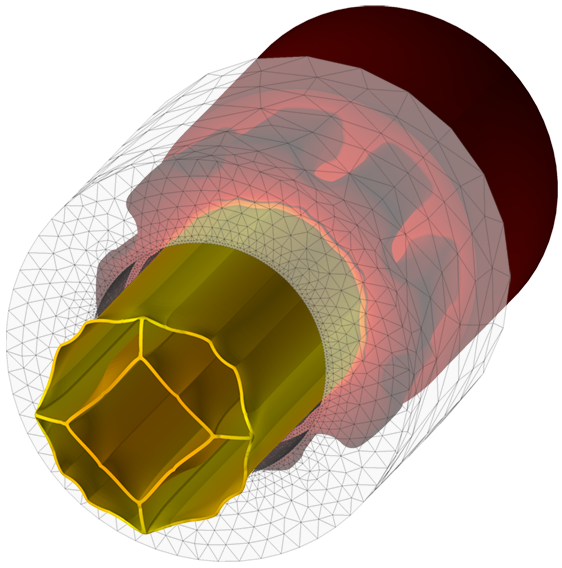

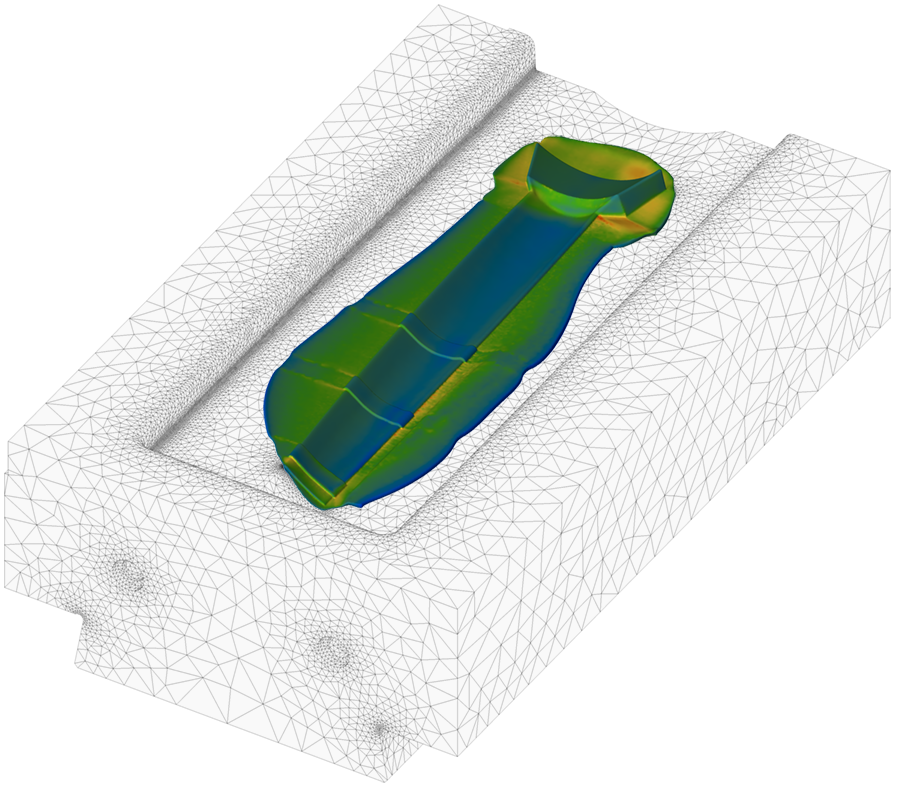

QForm UK Extrusion

QForm UK Extrusion is the only extrusion simulation QForm UK software module that calculates material flow fully coupled with the temperature and deformation of the dies taking into consideration distortion of tool surfaces, especially in the bearing area and simulates the material flow through this deformed shape of the die orifice. QForm UK Extrusion, combined with our QExDD program, provides die design integrated seamlessly with simulation.

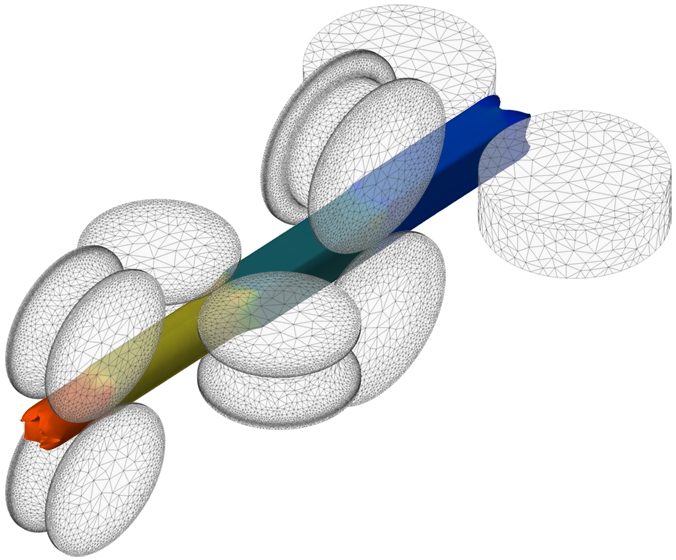

QForm UK Shape Rolling

QForm UK Shape Rolling is a special module of QForm UK for simulation of longitudinal and reverse rolling. The module is suitable for calculating the technological process of longitudinal rolling with a large number of passes. Easy setting of the source data and the ability to load a group of rolls with a given location in space from a CAD-system or from a special QKaliber CAD-system.

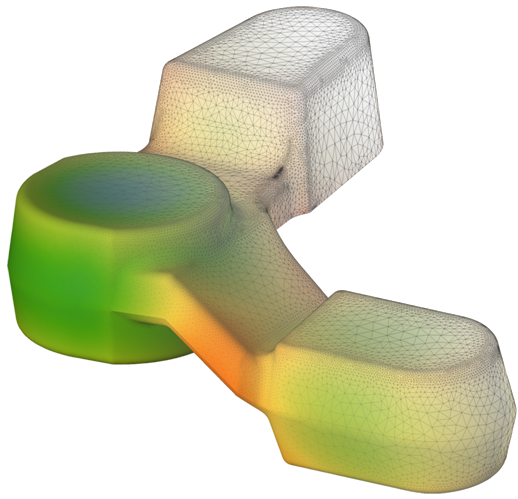

QForm UK Cold Forming

QForm UK Cold Forming is developed specially for simulation of cold forming operations and it helps to optimize material flow, reduce deformation load, predict tool life and produce defect free parts. QForm UK can handle complex die assemblies so it is possible to optimize complex pre-stressed dies with hard-alloy inserts and tire rings. QForm UK takes elasto-plastic tool deformations and elasto-plastic workpiece deformations into account with our specially developed models.

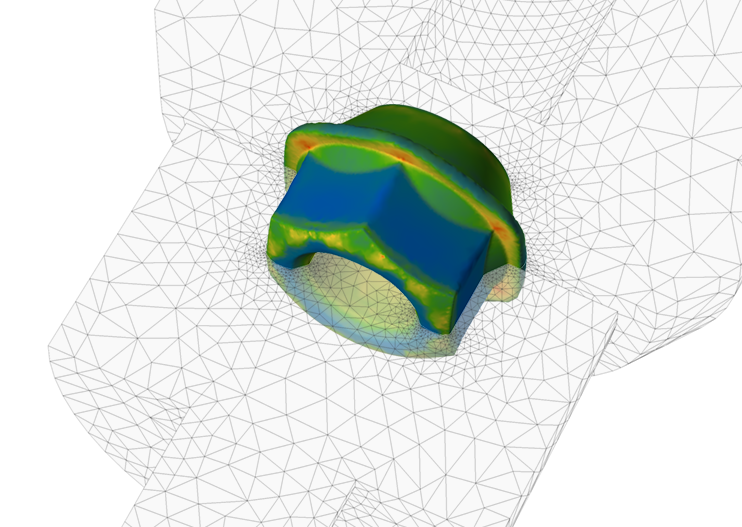

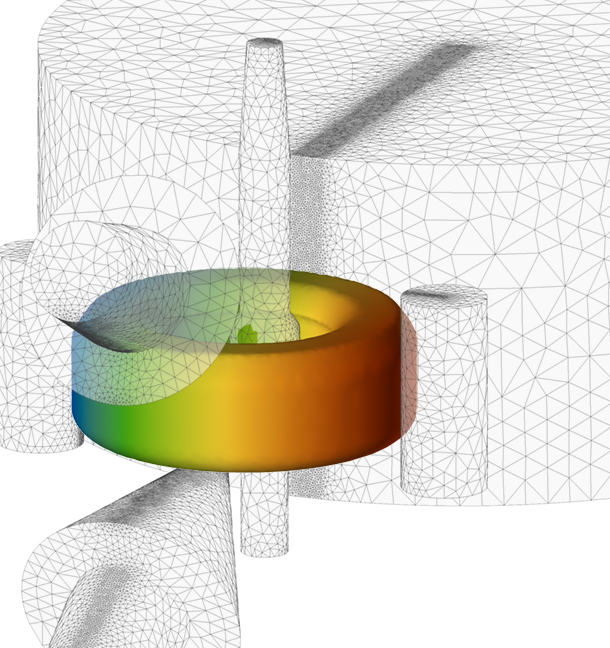

QForm UK Ring Rolling

Ring Rolling is a QForm UK software module specially developed for wheel and ring rolling processes simulation. The program is adapted to use data from modern rolling mill algorithms that significantly simplify the input of initial data required for simulation. Special calculation methods provide quick and accurate prediction of billet deformation with rectangular or shaped cross sections.

QForm UK Heat Treatment

QForm UK Heat Treatment is intended for predicting of the properties, such as hardness, ultimate strength, phase composition, stress state and the final shape of the detail. QForm makes it possible to estimate thermal stresses and distortion at the heating and cooling of a detail, which allows assessing the probability of cracking and more accurate determining the final shape of forged piece.

QForm UK Microstructure

QForm UK Microstructure is a special module for simulation of microstructure evolution during thermomechanical processing of steels, nickel-, titanium-, aluminum-based and other alloys. The module can perform calculation in the process chain with inheritance of calculation results and works for both 2D and 3D problems. The kinetics of recrystallization is described by the Johnson-Mehl-Avrami-Kolmogorov (JMAK) equation.

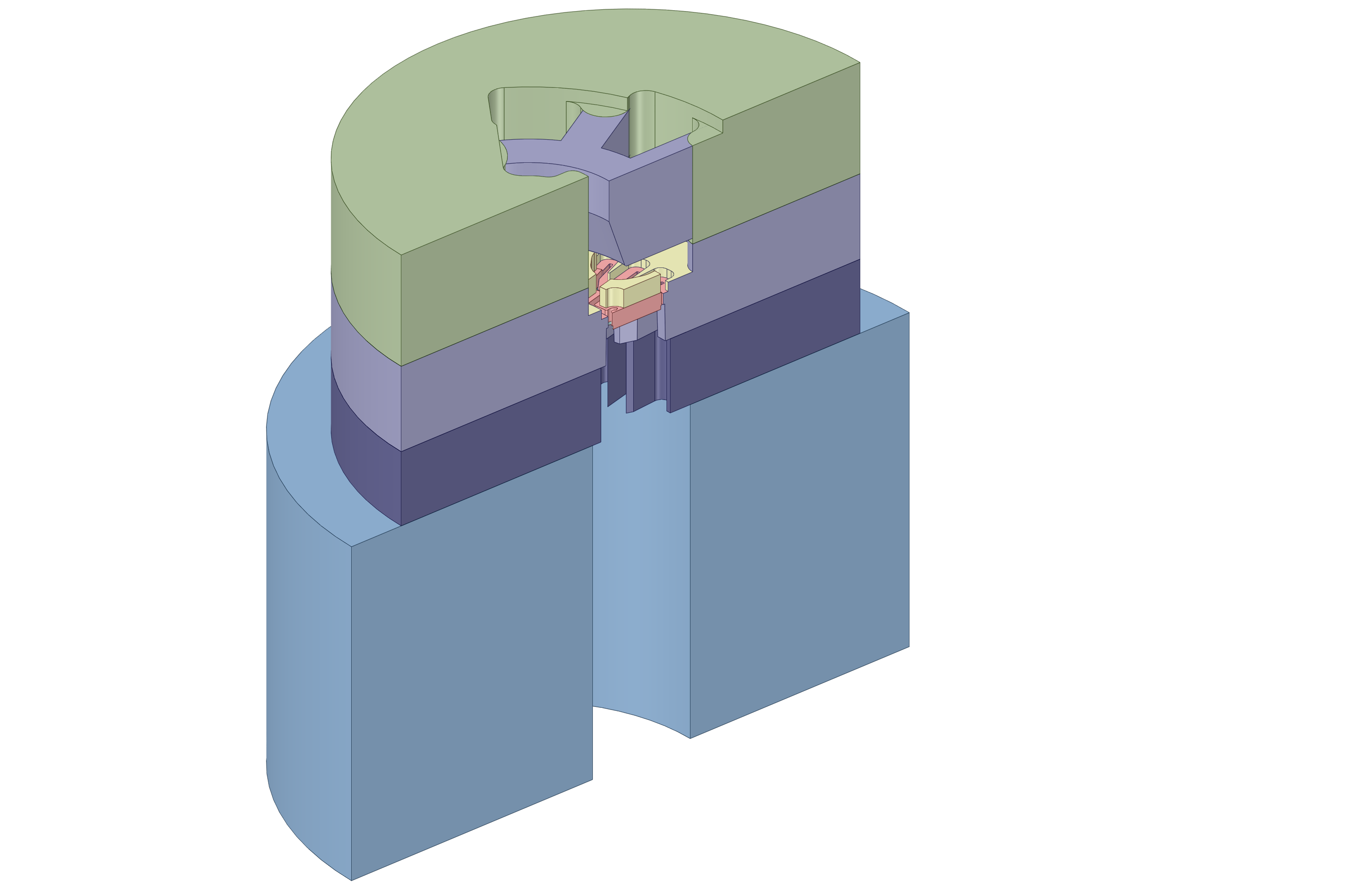

QForm UK Extrusion Die Designer

QForm UK Extrusion Die Designer is an automated system for 3D design of dies, mandrels and other parts of the tooling set for extrusion of aluminum hollow and solid profiles. This system helps create the solid model of a tooling set step-by-step using special parametric design tools. The user controls the design process by specifying the geometry and basic dimensions of the model.

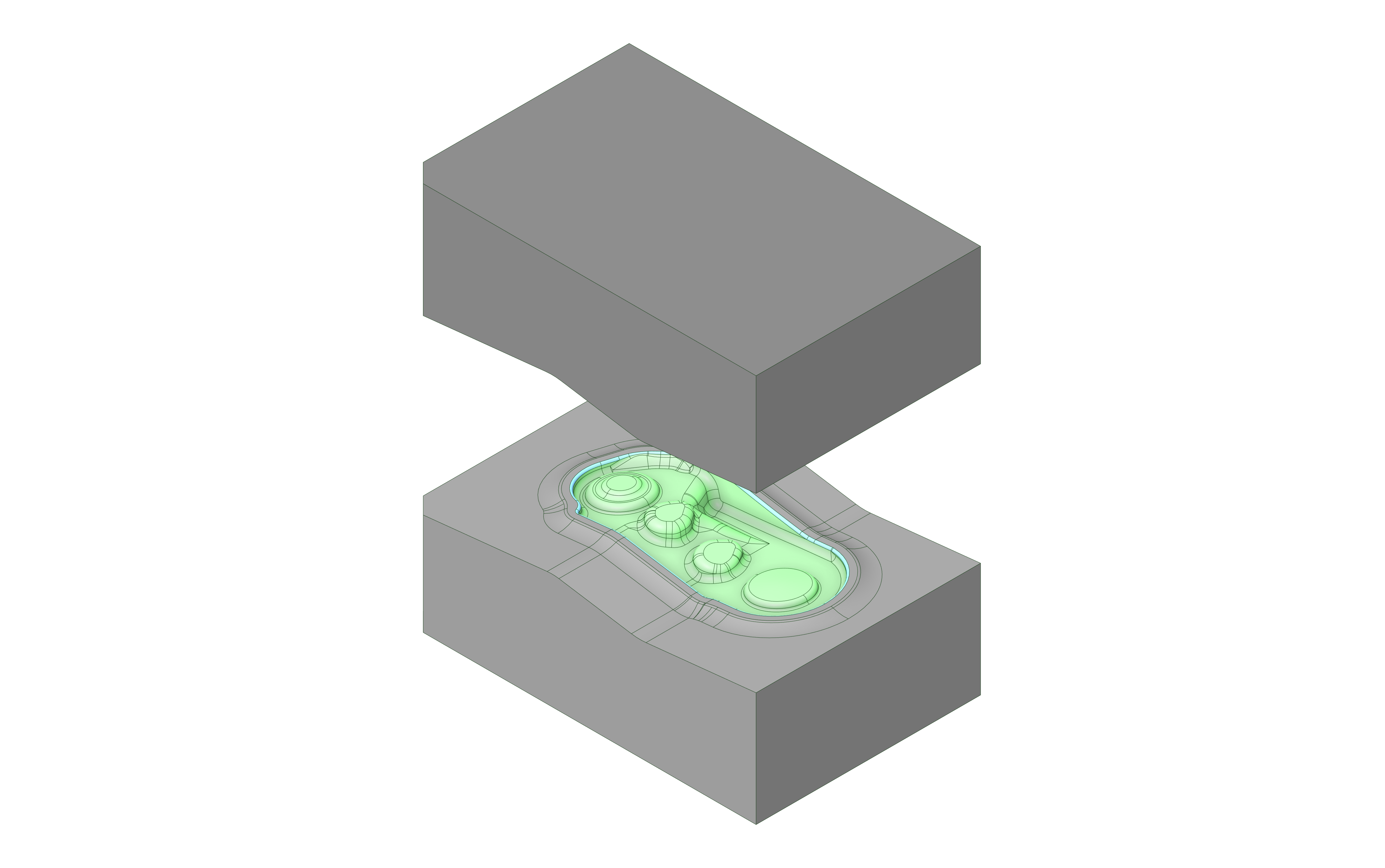

QForm UK Direct

QForm UK Direct is a computer-aided system for automated design of bulk forging preforming dies. QForm UK Direct makes it possible to create a 3D model of the preforming dies for bulk forging processes and import the geometry into QForm UK to verify the result. The principle of QForm UK Direct is simple, but the calculation methods are based on thorough scientific research and analysis. You just need to use the finish forging dies as initial data and after the automatic generation to pick the best surface for preliminary dies. Designed 3D models can easily be imported into the QForm UK to check the process.

QKaliber

QKaliber is a CAD system for the development and improvement of rolling processes for long products and section profiles. CAD system QKaliber is based on the analytical methods of the rolling shape design. The mutual work of the design system and simulation program provides solutions to the technological problems in the stages of preparing, adjusting and practical realization of the shape rolling technology.

© QForm Group FZ LLC, Fujairah-Creative Tower, P.O. Box 4422, Fujairah, United Arab Emirates

market@qform3d.com